Froth flotation is a critical process in mineral separation that relies heavily on the use of flotation reagents.

Among these reagents, collectors play a vital role in enhancing the hydrophobicity of target minerals, enabling their effective separation from gangue minerals.

Oil acid collectors, as a class of modern reagents, have gained significant attention due to their effectiveness and relatively low cost.

This article delves into the mechanisms behind oil acid collectors, their applications, and strategies for optimizing their performance in mineral flotation.

Oil Acid Collector Mechanisms

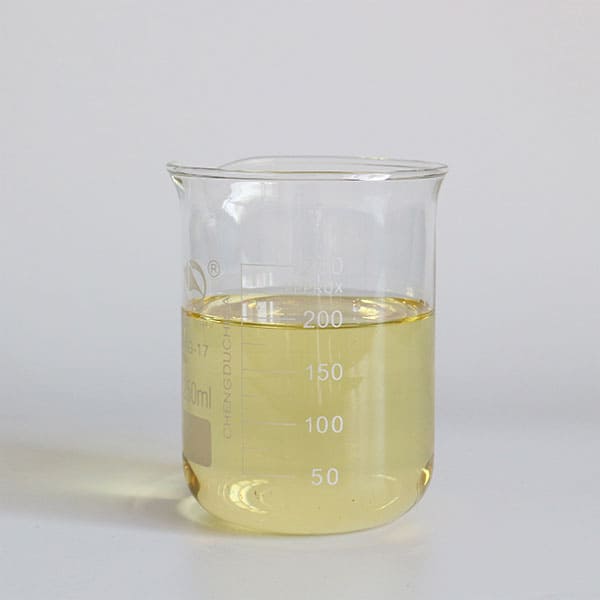

Oil acid collectors, primarily comprised of long-chain fatty acids such as oleic acid (C17H33COOH), function through a combination of surface chemistry interactions.

Their effectiveness is attributed to the following mechanisms:

1. Physical Adsorption

The long hydrocarbon chains in oil acid molecules interact with mineral surfaces through van der Waals forces. This physical adsorption enhances the hydrophobicity of the mineral particles, facilitating their attachment to air bubbles.

2. Ion Exchange Adsorption

Under specific pH conditions, oil acid anions (C17H33COO⁻) interact with positively charged mineral surfaces through electrostatic attraction. For instance, calcium ions on mineral surfaces can form complexes with oil acid anions, such as Ca(OL)₂, thereby improving collectibility.

3. Hydrophobic Aggregation

At higher concentrations, oil acid molecules form aggregates or hemi-micelles on mineral surfaces.

These structures significantly enhance the hydrophobicity of the particles, promoting their buoyancy in froth flotation.

4. Chemical Reaction Products

Oil acid can undergo oxidation or other chemical reactions in the pulp, forming derivatives such as alkyl-thiocarbonates.

These reaction products often exhibit higher collecting power, further improving mineral separation efficiency.

Applications of Oil Acid Collectors

The versatility and cost-effectiveness of oil acid collectors make them a preferred choice for a wide range of mineral flotation applications:

1. Base Metal Ores

Oil acid collectors are extensively used in the flotation of oxidized ores, including tin, tungsten, and antimony minerals.

They are particularly effective in separating these minerals from sulfide ores.

2. Rare and Precious Minerals

Their application extends to the recovery of rare minerals such as cassiterite and scheelite, where selectivity and efficient hydrophobicity are crucial.

3. Complex Ores

In mixed ores like lead-zinc and copper ores, oil acid collectors aid in the differential flotation of minerals, ensuring optimal recovery rates.

Optimization Strategies for Oil Acid Collectors

1. pH Control

The performance of oil acid collectors is highly pH-dependent.

Adjusting the pulp pH ensures the optimal dissociation of oil acid molecules, maximizing their adsorption on target minerals.

2. Dosage Management

The dosage of oil acid must be carefully optimized; excessive concentrations can lead to entrainment of non-target minerals, while insufficient amounts may result in poor collection efficiency.

3. Synergistic Effects

Combining oil acid with other flotation reagents, such as modifiers or frothers, can significantly enhance its performance.

For example, the addition of activators can improve the selectivity of oil acid collectors in complex ores.

4. Temperature Management

The solubility and adsorption behavior of oil acid are temperature-sensitive.

In cold climates, heating the pulp or using auxiliary solvents may be necessary to maintain reagent effectiveness.

5. Environmental Considerations

Despite their relatively low environmental impact, oil acid collectors should be used with caution.

Spill control and waste management practices are essential to mitigate potential ecological effects.

Case Study: Oil Acid Collectors in Tin Flotation

In a recent industrial application, the use of oil acid collectors in cassiterite flotation resulted in a 15% increase in tin recovery rates.

The optimization of pH and reagent dosage played a crucial role in achieving this outcome.

Conclusion

Oil acid collectors are indispensable in modern froth flotation technologies, offering a balance of effectiveness, selectivity, and cost-efficiency.

By understanding their mechanisms of action and implementing targeted optimization strategies, operators can maximize mineral recovery while minimizing operational costs.

As research continues to uncover new applications and refinement techniques, oil acid collectors are poised to remain a cornerstone in mineral separation processes.